Atras

Atras-

Carro 0 Articulo(s)

Estas Viendo:

Precio : Q2,991/set

Precio : Q2,991/set

Atras

Atras Precio : Q2,991/set

Precio : Q2,991/set

Cortadora giratoria de papel

Ojilladora

Cortadora giratoria de papel

Ojilladora X/Y Digitrim Automatic Cutter

Digitrim Automatic Cutter Spare Parts

Limpiador ultrasónico

X/Y Digitrim Automatic Cutter

Digitrim Automatic Cutter Spare Parts

Limpiador ultrasónico

Maquina de grabado Laser

Maquina de grabado Laser Maquina de Corte Fibra Laser para Metal

Maquina de Corte Fibra Laser para Metal Máquina de soldadura por láser

Máquina de soldadura por láser Router y Grabadora CNC

Router y Grabadora CNC Cortadora de Cama Plana Digital

Engraving Blanks

Cortadora de Cama Plana Digital

Engraving Blanks

Material para Muescas y Letras

Maquina de acabados de Acrílicos

Metal Profile Making Machine

Material para Muescas y Letras

Maquina de acabados de Acrílicos

Metal Profile Making Machine

Automatic Heat Press

Maquina Prensadora de Calor de Gran Formato

Automatic Heat Press

Maquina Prensadora de Calor de Gran Formato Maquina de presión de calor para Tazas y Plato

Cap Heat Presses

Maquina combo de presión de calor

Maquina de presión de calor 3D

Kit de inicio para prensa de calor

Refacciones para Prensa de calor

Armadora de Broches

Tinta de sublimación

Maquina de presión de calor para Tazas y Plato

Cap Heat Presses

Maquina combo de presión de calor

Maquina de presión de calor 3D

Kit de inicio para prensa de calor

Refacciones para Prensa de calor

Armadora de Broches

Tinta de sublimación

DTF / DTG Ink

Direct Printing Inks

Tinta Eco y cartuchos

Tinta base solvente

DTF / DTG Ink

Direct Printing Inks

Tinta Eco y cartuchos

Tinta base solvente Tinta UV

Tinta UV

Cortadora giratoria de papel

Ojilladora

Cortadora giratoria de papel

Ojilladora X/Y Digitrim Automatic Cutter

Digitrim Automatic Cutter Spare Parts

Limpiador ultrasónico

X/Y Digitrim Automatic Cutter

Digitrim Automatic Cutter Spare Parts

Limpiador ultrasónico

Maquina de grabado Laser

Maquina de grabado Laser Maquina de Corte Fibra Laser para Metal

Maquina de Corte Fibra Laser para Metal Máquina de soldadura por láser

Máquina de soldadura por láser Router y Grabadora CNC

Router y Grabadora CNC Cortadora de Cama Plana Digital

Engraving Blanks

Cortadora de Cama Plana Digital

Engraving Blanks

Material para Muescas y Letras

Maquina de acabados de Acrílicos

Metal Profile Making Machine

Material para Muescas y Letras

Maquina de acabados de Acrílicos

Metal Profile Making Machine

Automatic Heat Press

Maquina Prensadora de Calor de Gran Formato

Automatic Heat Press

Maquina Prensadora de Calor de Gran Formato Maquina de presión de calor para Tazas y Plato

Cap Heat Presses

Maquina combo de presión de calor

Maquina de presión de calor 3D

Kit de inicio para prensa de calor

Refacciones para Prensa de calor

Armadora de Broches

Tinta de sublimación

Maquina de presión de calor para Tazas y Plato

Cap Heat Presses

Maquina combo de presión de calor

Maquina de presión de calor 3D

Kit de inicio para prensa de calor

Refacciones para Prensa de calor

Armadora de Broches

Tinta de sublimación

DTF / DTG Ink

Direct Printing Inks

Tinta Eco y cartuchos

Tinta base solvente

DTF / DTG Ink

Direct Printing Inks

Tinta Eco y cartuchos

Tinta base solvente Tinta UV

Tinta UV

Codigo del articulo:SPM-TJ-SPE-BQM240

Precio Unitario : Q 2,991/set (Aviso de Descuento) (Tiempo entrega 69-89 días)

set(s)

Costo Total :

GTQ

Q2,991

set(s)

Costo Total :

GTQ

Q2,991

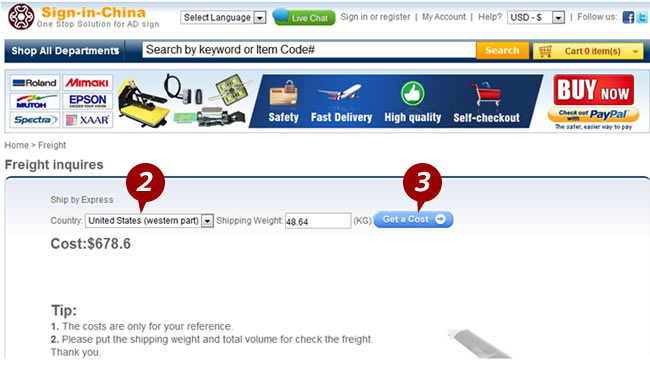

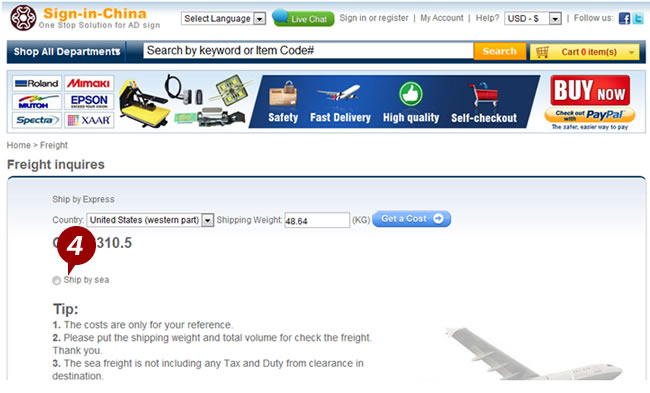

Peso de Envio:

68.9lb (31.3kg)

Flete

Flete

El vendedor asume toda la responsabilidad de este listado

Cantidad: Pais:

| Envío y manipulación | Para | Servico | Entrega* |

| US $75.00 | Estadpos Unidos | Entrega express: TNT/DHL/FEDEX/UPS | Estimado entre |

| Tiempo de Manejo |

| Enviará generalmente dentro de 3 días hábiles después de recibir el pago aprobado. |

|

Tenemos 4 almacenes en el extranjero en todo el mundo que ahora incluye: Rusia, EE.UU., Brasil y México. y Estamos creando otro en Europa. Normalmente, enviaremos su pedido desde el almacén más cercano a usted. si las existencias cerca de usted están agotadas, le enviaremos su pedido a usted directamente de China. |

|

|

| Forma de pago |

|

|

Historial De Transacciones

Transacciones:

One Color Baseball Cap Soft Hat Mask Screen Printing Machine

This machine is mainly used for the printing of various soft materials cambered surface and irregular cap mask ,such as cotton fabric, chemical fiber fabric, sponge, etc. For example, baseball cap, sun cap, duck cap, fisherman cap, leifeng cap, Zhongshan cap, octagonal cap all kinds of soft material caps, as well as masks of various materials and so on, the use of this machine can effectively improve the printing quality, improve the printing efficiency.

Advantage:

1. Positioning by adjusting the radian of the cap and mask: using the adjustable arc material; adjust the radian of the arc according to the need.

2. The Positioning of cap and mask: place the cap or mask on the tooling, and position the cap and mask on the tooling vertical board by 4-6 magnets on three or four sides; The hat or mask will not move; Take off the hat just take off the magnet, convenient and quick; Easy to set the hat, the hat does not deviate.

3. Stainless steel cambered plate can be bent a little from left to right in accordance with the arc of the hat; To meet the radian requirements of the cap printing surface, so as to ensure that the screen plate and printing surface arc as parallel as possible, to ensure accurate printing positioning and the quality of printing.

Functions:

1. The bottom of the machine and the positioning platform can be moved back and forth, and a drag positioning device is set; Drag the platform out, cover with a hat or mask, and the magnet adsorbs to fix, push the machine to print; Pull out the platform, remove the magnet, remove the hat or mask; Pull out and push in can be accurately positioned by positioning ball screws on both sides of the platform.

2. The main machine can be micro adjusted by manual knobs from left to right, up and down, up and down can move 6.7"(170 mm); There is with a handle lock; Left and right can adjust 20mm, tighten and lock.

3. The machine adopts 0.04"(1 mm )stainless steel plate, the screen frame directly fixed on both sides of the frame beam; Screen plate can move 5" (130mm) front and rear; Screen plate installation beam can be finished by adjusting the screen radian by hand screw; After adjusting to the same radian as the printing surface, lock the screws at both ends of the two beams.

4. The whole magnet is covered with a rubber layer, adsorption force is large, at the same time it will not damage the hat or mask; Magnet with handle, easy to access, fast, labor-saving.

5. The machine is equipped with two flexible stainless steel frames; Inner size is 4"x 7.5" /100 x 190 mm (outer size is 5" x 7.9" /130 x 200 mm); 4" x 9.5"/100 x 240 mm (outer size 5"x 9.8"/130 x 250 mm); Suitable for most kinds of soft hat printing patterns.

6. All parts of the machine are advanced electrostatic spraying surface treatment, corrosion resistance, acid and alkali resistance, cleaning resistance, long - term use without rust.

Usage methods and procedures (for reference only):

1. Drag out the platform, cover the substrate on the tooling and fix it with a magnet.

2. Adjust the screws on both sides of the cambered settings according to the radian of the substrate to achieve the condition that the setting and the cambered surface of the substrate basically coincide;Push the platform into the machine for positioning.

3. Install the screen frame with a blank mesh on the frame rack.

4. Adjust the screen frame radian and cap printing cambered surface basically matched, and basically determine the printing pattern on the screen plate position.

5. Takedown the screen plate and make a plate according to the position of the pattern.

6. In order to prevent ink overflow, the screen plate around can be affixed with a sealing strip.

7. Install the finished screen plate and adjust it to the appropriate position, Install the fixed screws on both sides of the screen plate to lock and print.

Details:

Configured with relevant tools and materials:

1.1 piece 8 cm scoop coater

2. One for each of the two stainless steel cambered screen plates

3. 1 piece 8cm metal scraper (including rubber strip)

4.1 roll screen plate edge sealing tape

Package:

Gross weight: 68.9 lb /31.3kg

Packing size: 25.6 x 22.5 x 20.9 inch /65 x 57 x 53 cm

0 ( )

0 ( )Escriba un comentario para One Color Baseball Cap Soft Hat Mask Screen Printing Machine

Learn more about us from the following links:

19th Reklama Pholygraf Trade Fair 2012

ISA International Sign Expo 2012

Buyers say:

Jackson, Andy and David from UK

Adam Fernanders from South Africa

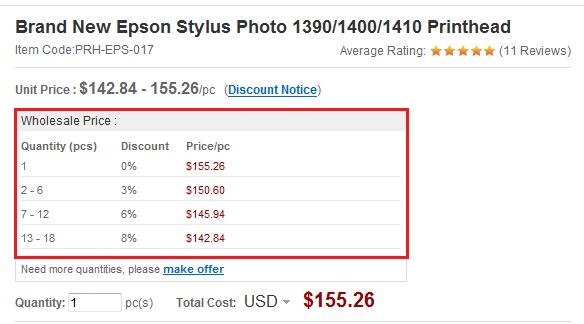

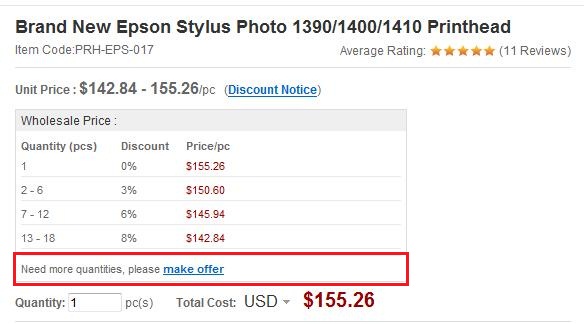

a) The Stepped Price

According to the different procurement quantities of customers, Sign-in-China.com formulates different price levels for commodity. Hence, your purchase price will be ultimately attributed to the procurement quantity.

The Stepped Prices shown on the product page is as following:

b) Trial Order Price / Sample Price

We offer free samples or some lower priced products(the product price plus shipping cost only)for our customers easily to experience our products and services from purchasing.

For details, please click:

http://www.sign-in-global.com/product/sampleproduct.html

c) Limited Time Offers

Every Tuesday Sign-in-China.com releases the latest products for Limited Time Offer, and after one week, the original price will be recovered. We sincerely expect your timely attention to the discount activities of Limited Time Offers on Sign-in-China.com.

For details, please click:

http://www.sign-in-global.com/product/discount.html

d) Flash Wholesale

Every Monday Sign-In-China.com and cooperation factory jointly campaigns the Flash Wholesale products for bulk purchase customers, and after a week, the original price will be receovered. We sincerely expect your timely attention to the preferential activities on Sign-In-China.com.

For details, please click:

http://www.sign-in-global.com/product/featuredproduct.html

e) You decide the prices for Bulk Orders

If the commodity quality you choose beyonds the quantity of fourth step price on Sign-in-China.com, or if you think the website stepped prices don’t meet your bulk purchase demand, you can use our "Make Offer" service on Sign-in-China.com to fill out your planned purchase quantity and target price then submit as a Bulk Order, for which we will review and endeavor to realize the deal with you.

If you need bulk order , please enter here to Make Offer:

a) PayPal online payment

https://www.paypal.com/webapps/mpp/buying-online

b) PayPal direct payment (our PayPal account: lyh@chinasigns.cn)

https://www.paypal.com/webapps/mpp/make-online-payments

c) Credit card payment (through PayPal gateway, some areas may be restricted)

https://www.paypal.com/us/webapps/helpcenter/article/?articleID=94038&topicID=11500008&m=TTQ

d) Bank transfer

https://www.paypal.com/us/webapps/helpcenter/article/?articleID=94040&topicID=11500008&m=TTQ

e) Telegraphic Transfer (T/T) payment

(1) Place an order

(2) Get the bank account information of Sign-in-China.com

(3) Make the payment at the bank, and get the Payment Receipt

(4) Send the Payment Receipt to service@sign-in-global.com

(5) Receive the Tracking Number of your order

(6) Wait for your order.

Bank transfer payment information:

on the product page and submit your questions, we will reply you as soon as possible.

on the product page and submit your questions, we will reply you as soon as possible.

Learn more about us from the following links:

19th Reklama Pholygraf Trade Fair 2012

ISA International Sign Expo 2012

Buyers say:

Jackson, Andy and David from UK

Adam Fernanders from South Africa

For details, please refer to the following:

a) Bank Transfer (T/T) payment

(1) Place an order

(2) Get the bank account information of Sign-in-China.com

(3) Make the payment at the bank, and get the Payment Receipt

(4) Send the Payment Receipt to service@sign-in-global.com

(5) Receive the Tracking Number of your order

(6) Wait for your order.

Bank transfer payment information:

b) PayPal online payment https://www.paypal.com/webapps/mpp/buying-online

c) PayPal direct payment (our PayPal account: lyh@chinasigns.cn) https://www.paypal.com/webapps/mpp/make-online-payments

d) Credit card payment (through PayPal gateway, some areas may be restricted) https://www.paypal.com/us/webapps/helpcenter/article/?articleID=94038&topicID=11500008&m=TTQ

e) Bank transfer (through PayPal gateway) https://www.paypal.com/us/webapps/helpcenter/article/?articleID=94040&topicID=11500008&m=TTQ

f) Western Union Payment

Receiver’s First name: Zifei Receiver’s Last name: Li Address: 4th Floor., Building No.8, Community No.12. Advanced Business Park, No.188 Western Road of the 4th Ring, Fengtai, Beijing.

a) Confirm if your credit card requires verification: https://www.paypal.com/us/webapps/helpcenter/article/?solutionId=10568&m=SRE

b) Confirm if you have exceeded the limitation of maximum amount https://www.paypal.com/us/webapps/helpcenter/article/?solutionId=11516&m=SRE

c) Confirm if you have any other restrictions https://www.paypal.com/us/webapps/helpcenter/article/?articleID=94053&m=SRE

If you failed to make payment via PayPal, please choose Bank Transfer(T/T) or Western Union Payment.

We will ship your order by Express or by sea and usually the carriers are FedEx, TNT, UPS, DHL, or EMS. It shall be quite safe during shipping with substantial package. It shall be quite safe during shipping with substantial package. Additionally, we will purchase insurance as a gift for your package.

For details, please click the following links:

Changes & Returns: http://www.sign-in-global.com/info/ChangesandReturns.html

Warranty: http://www.sign-in-global.com/info/QualityWarranty.html

Recibe gratis actualizaciones, descuentos y ofertas especiales para ganar productos gratis y premios en efectivo

www.sign-in-guatemala.com. es el mayor proveedor en línea de productos de publicidad en el mundo y especializados en el suministro de una solución integral para los clientes al seleccionar equipos de Publicidad, materiales de consumo articulos publicitarios, productos de publicidad, etc. También el centro de servicio en el extranjero autorizado por la Asociación China de impresión, de inyección de tinta, para lo cual hemos establecido sucursales en el extranjero, en 6 países extranjeros con el fin de brindar un mejor servicio a nuestros clientes en todo el mundo. Nuestros productos cubren todo el campo de la Publicidad y la señalización y todos los productos que suministramos se hacen de conformidad con las normas internacionales de calidad, como resultado de que, en la actualidad, tenemos más de 9000 productos en línea para la venta. Desde que implementamos la compra centralizada, todos los productos se cotizan a precios competitivos.